Electric cars are today more expensive than their internal combustion equivalents. Even though they are much simpler from a construction point of view (a heat engine has dozens of moving parts, while an electric one only has one), they are burdened, among other things, because so few units are manufactured.

In the automotive industry, it is clear that to manufacture affordable electric cars, it will be necessary to achieve significant economies of scale: the more vehicles produced, the sooner the investments made in their development will be amortized and the lower their production costs will be. Within this strategy, scalable modular platforms will play an important role.

A modular platform makes it possible to build different types of cars (utility vehicles, saloons, SUVs, vans…) of different sizes starting from a common base, which greatly simplifies vehicle development and allows a significant reduction in production costs. This solution has been in use with thermal vehicles for years and will be of great importance in the electric category.

We can distinguish two types of modular platforms for electric cars depending on the approach followed by manufacturers: multi-energy, which have been developed to accommodate thermal, hybrid, and electric powertrains; and dedicated ones, which have been created from the beginning for 100% electric models.

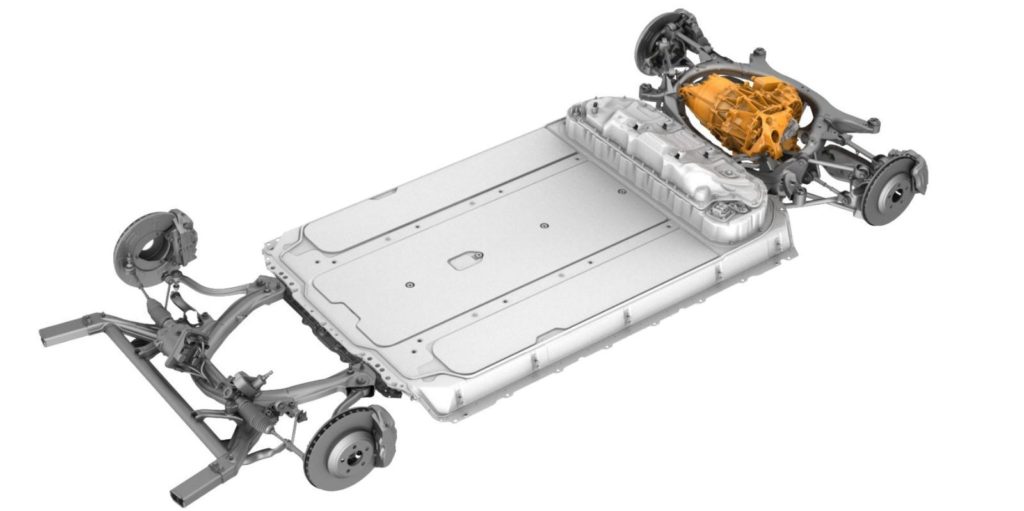

CMF-EV platform of the Renault-Nissan-Mitsubishi Alliance

Multi-energy platforms will be beneficial during the first stages of the transition to electric mobility. They will allow electric cars to share parts and production lines with high-volume thermal models, amortizing themselves before their development and allowing them to take full advantage of synergies with the rest of the range.

Dedicated platforms, for their part, are much simpler because they do not have to meet the requirements to accommodate several different types of the powertrain. By being adapted to a specific type of propulsion system, they allow optimizing the mechanical distribution (engines electric are smaller than thermal ones so that the hood can be shortened, the passenger compartment can be moved forward, the overhangs are reduced, the wheelbase is extended, etc; while the situation of the batteries in the underbody leads to a better weight distribution).

Examples of multi-energy platforms are the CMF-B/EV of the Renault-Nissan-Mitsubishi Alliance, the FAAR and CLAR of BMW, the future MMA Mercedes-Benz, the eCMP, and eVMP of Stellantis or the CMA and SPA of Volvo. Regarding the dedicated platforms, we should highlight the CMF-EV of the Renault-Nissan-Mitsubishi Alliance, the future Neue Klass of BMW, the SEA of Geely, the Ultrium of General Motors, the E-GMP of Hyundai, the MEA Mercedes-Benz, and the MEB and PPE of the Volkswagen Group.

The quintessence of modular platforms for electric cars will be the future SSP architecture of the Volkswagen Group, which will arrive in 2025 to replace the MEB (volume models) and PPE (premium models). This highly scalable platform can be used in models from segment B to segment F, with all kinds of bodies and equipping up to four electric motors, which will allow front, rear, or all-wheel-drive configurations.

According to numerous experts, the young American manufacturer Tesla leads the vast majority of its electrical technology rivals. However, where the brand led by Elon Musk cannot compete is in economies of scale. Despite betting on solutions that seek to maximize cost savings, such as the use of racks formed from large pieces of function, the company does not have modular platforms.

the Model 3 and Model Y use one platform, and the Model S and Model Y a different one. The Cybertruck pick-up will also be based on a specific architecture, as is suspected to be the case with the future Roadster. Although the firm’s compact future uses a modified version of the architecture seen in the Model 3 and Model Y, the truth is that Tesla does not have a modular platform as such.

This could pose a problem for the brand in the future as, thanks to economies of scale, rivals could quickly achieve a higher profit margin and lower prices. At the moment, Tesla has not confirmed its plans for the future, but it would not be surprising if it later announced the development of a typical architecture for its entire fleet of passenger cars.