A new video released by Tesla featuring the California-based automaker’s new Giga Press casting machine, shows how it produces a giant single-piece rear body casting for the Model Y.

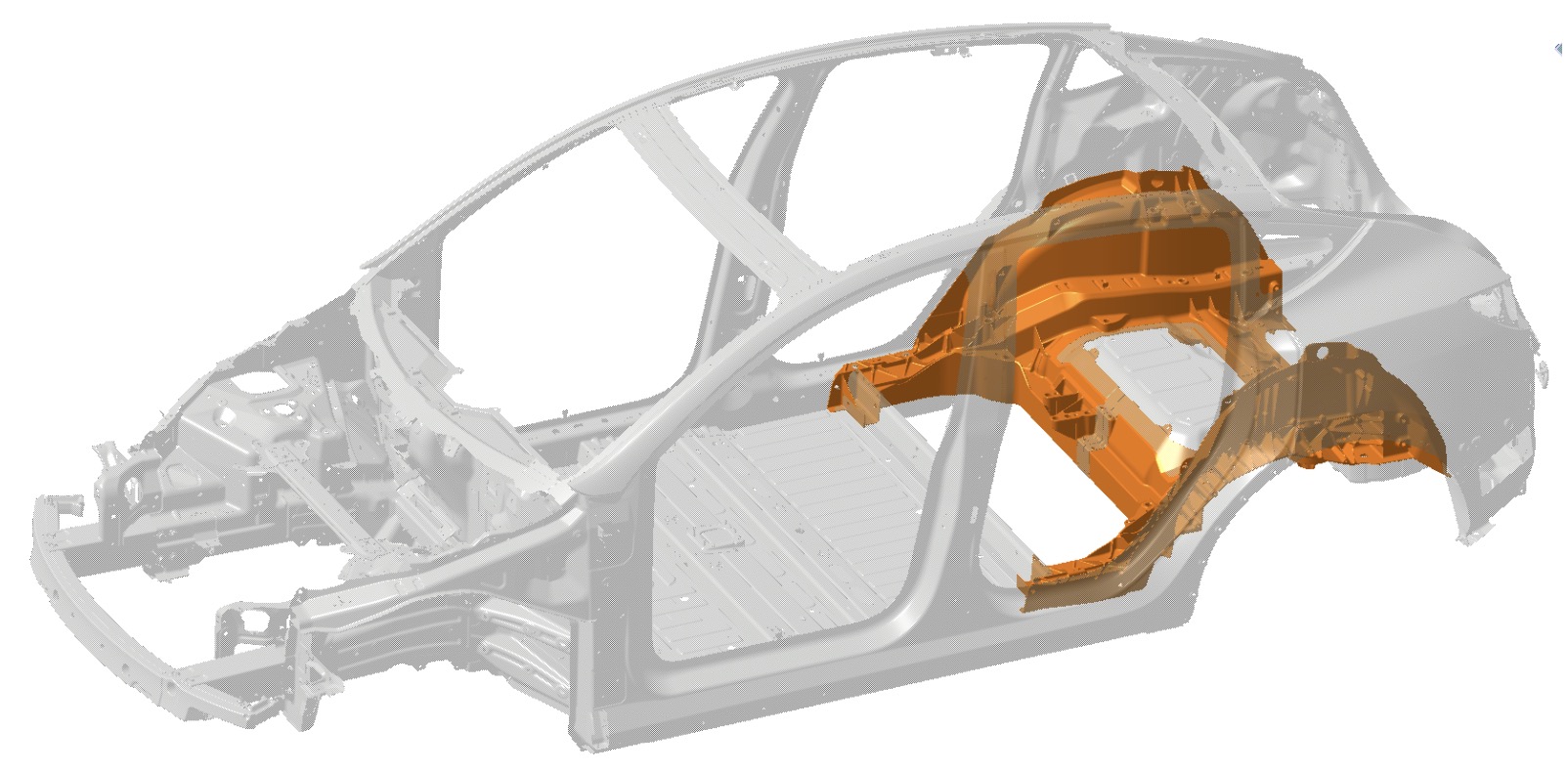

Casting technology has been a main focus for the EV giant in recent years in order to cut production cost. The Model Y was the original model in which we saw Tesla use bigger casting parts. The Fremont Model Y has a rear under-frame constructed from two large aluminum blocks (top), rather than the seventy pieces of stamped steel that make up the same section in the Model 3 (bottom):

Last month, The Next Avenue reported that Tesla had begun producing the Model Y with a single-piece rear casting thanks to Tesla’s first Giga Press, installed at the Fremont factory.

Tesla’s Giga Press is the first of its kind and was produced by Idra Group in Italy. It has a clamping force of 55,000 to 61,000 kilonewtons (5,600 to 6,200 tf).

Tesla plans to deploy more Giga press machines at its other factories and has reportedly ordered several more. The EV giant even recently received a delivery of one at Gigafactory Texas.

With production of the Model Y up and running at Gigafactory Shanghai. Tesla has released a new video of its Giga Press at in operation:

According to Elon Musk the reduction in parts greatly simplified Tesla’s body production line eliminated about 300 robots on the line. Not only that, it also improves the vehicle’s quality as the larger casting parts make for a more consistent body without the need to line up several different variables.

Tesla’s is expected to take is larger casting efforts even further while it plans to produce the front underbody of the chassis using the same process. The Model Y is expected to first be produced with a single-piece casting rear later this year at Gigafactory Berlin.