Going off of new images of a Model Y unit, Tesla has begun production and delivery of its electric SUV with a large single-piece rear casting.

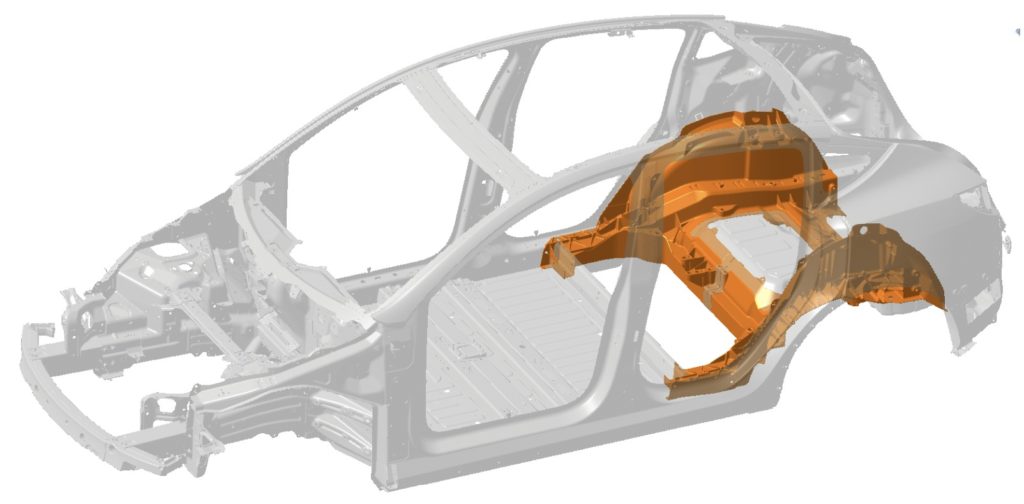

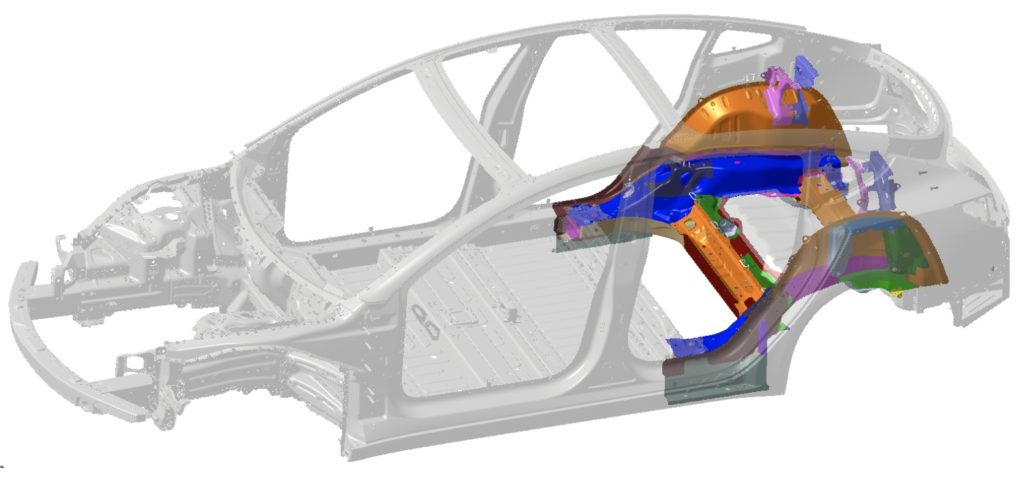

The Model Y was the original model in which we saw Tesla use bigger casting parts. The Fremont Model Y has a rear under-frame constructed from two large aluminum blocks (left), rather than the seventy pieces of stamped steel that make up the same section in the Model 3 (right):

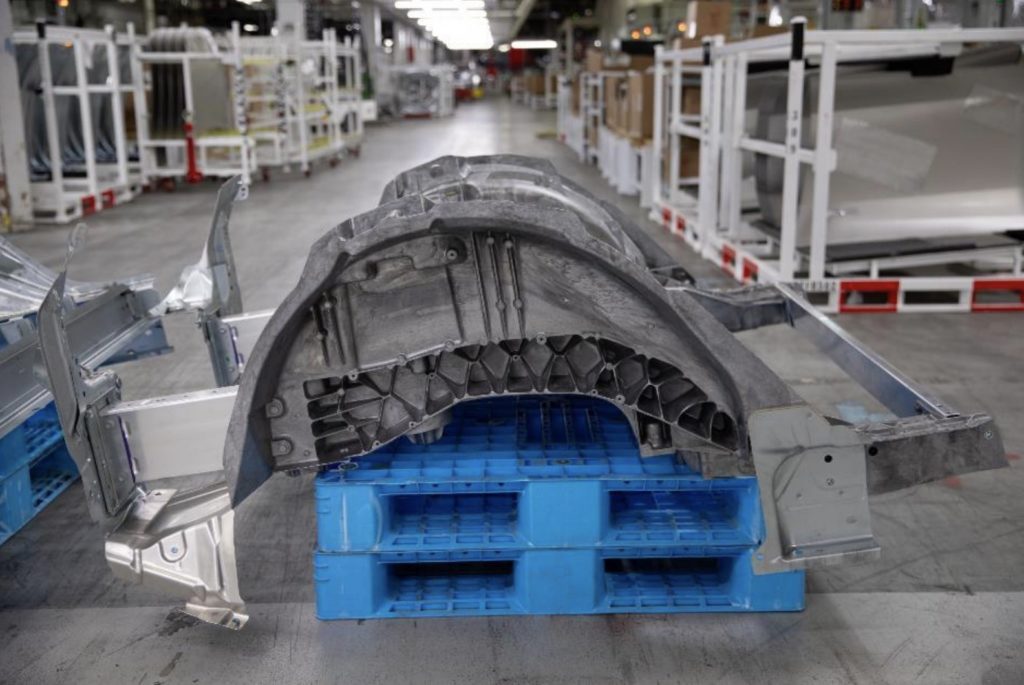

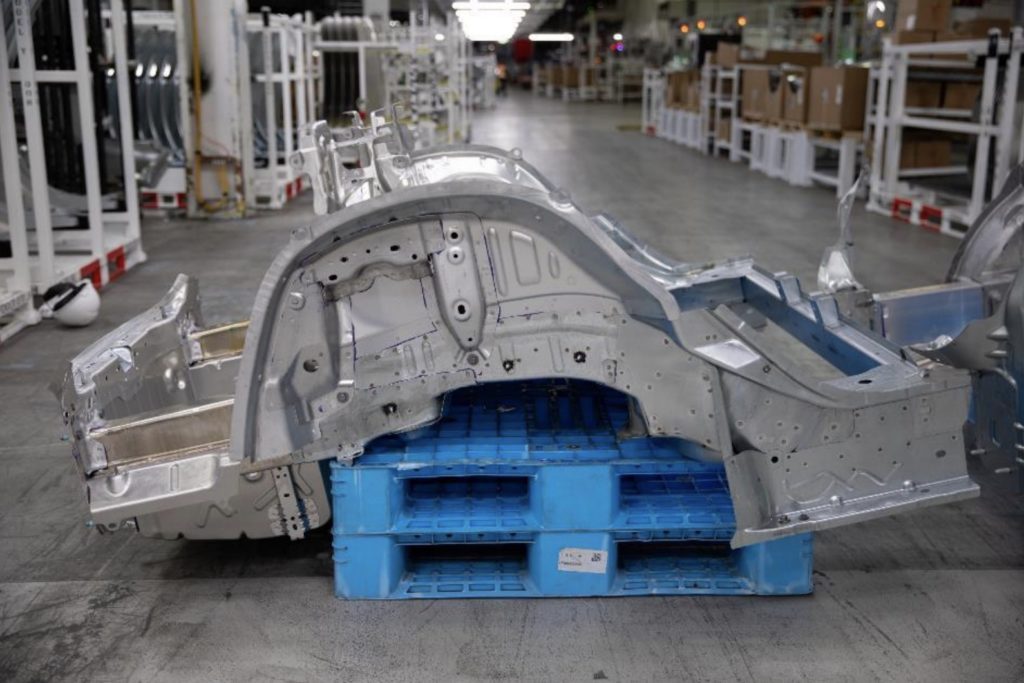

According to Tesla CEO, Elon Musk said his company will take it one step further by merging the two piece rear frame into just one.

The Next Avenue reported last year that the California-based company’s Fremont factory was receiving what was said to be the world’s largest casting machine. After a few weeks Tesla China announced the mammoth machine was up and running and the goal was to make the entire rear underbody of the electric SUV in one single part.

Although there was no real timeline on when these casting improvements would be present on the Model Y we have confirmation via tweet that they currently are.

Model Y owner Tony Pham took to Twitter to show the new part on his electric SUV produced in late December. Pham stumbled upon the casting improvement when removing the lining of his trunk to install a third-party accessory:

When looking at the photo it is pretty clear there is no joint in the middle and it presents as single piece. With the addition of new larger casting machines at all of its Gigafactory’s in the future, the EV giant will be displaying the benefits of unibody casting in no time.

The introduction of a single piece casting not only allows a significant reduction in production costs, but this method should also improve the car’s passive safety.