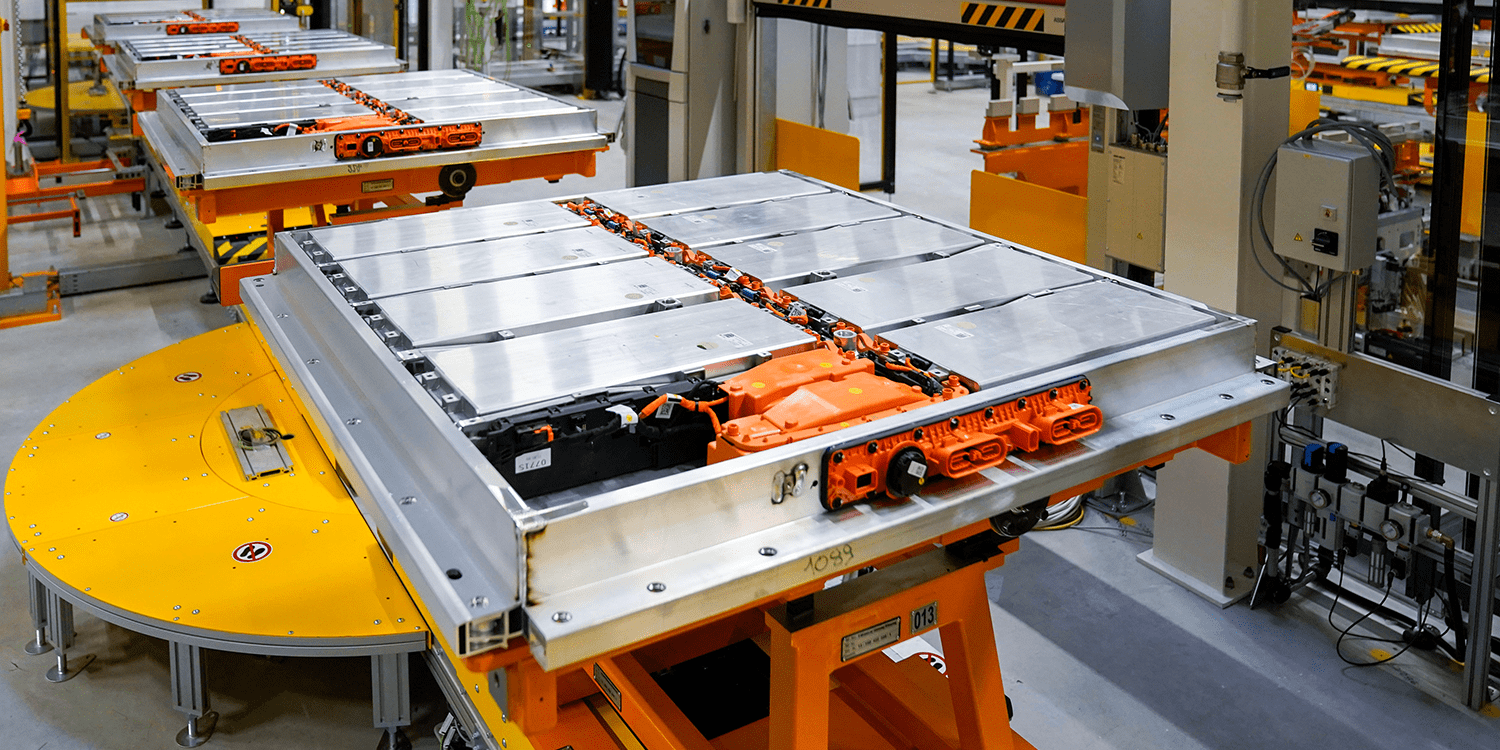

During the “Power Day” event held earlier this week, Volkswagen showed the industry its ambitious plans in the field of batteries and charging infrastructure. It announcing developments such as adopting a unified prismatic cell format or the construction of six Gigafactories on European soil by 2030.

One of the aspects in which VW placed more emphasis was the recycling of batteries, stating that thanks to hydrometallurgy, it would be possible to recover up to 95% of the materials that make up the cells (the remaining 5% would correspond to the separators of the battery, which cannot be recycled), bringing electric cars closer to the long-awaited circular economy.

During its presentation, Volkswagen gave as an example a 400 kg battery, which contains 126 kg of aluminum, 71 kg of graphite, 41 kg of nickel, 37 kg of electrolyte, 22 kg of copper, 21 kg of plastic, and 82 kg of other types of materials. Its recovery, in addition to having enormous potential for protecting the environment, could turn out to be more profitable than obtaining new raw materials in mines.

The recycling process is as follows: after subjecting the packs to a complete unloading process, the housings and peripheral elements are removed. The modules are then crushed, and the liquid electrolyte is removed. Once the resulting granules (black powder, lithium, nickel, manganese, cobalt, and graphite) have dried, aqueous solutions are used to separate the different metals (hydrometallurgy).

Once all the materials have been separated, they can be reused to manufacture new cells. This process will be very beneficial for the environment because it will reduce the need to extract new raw materials from the mines and avoid polluting waste once the useful life of the batteries ends. It will also mean a reduction in carbon dioxide emissions.

Beyond the environmental benefits of the battery recycling process, the cost reduction associated with this circular economy will make it possible to create cheaper electric cars. The first recycling plant of the VW Group is located in Salzgitter (Germany) and has been operating since last January.