Thanks to Magna’s new eBeam technology, trucks, pickups, and light trucks can become zero-emission vehicles. In this way, the recycling of older and more polluting cars is promoted into new clean alternatives that extend their useful life.

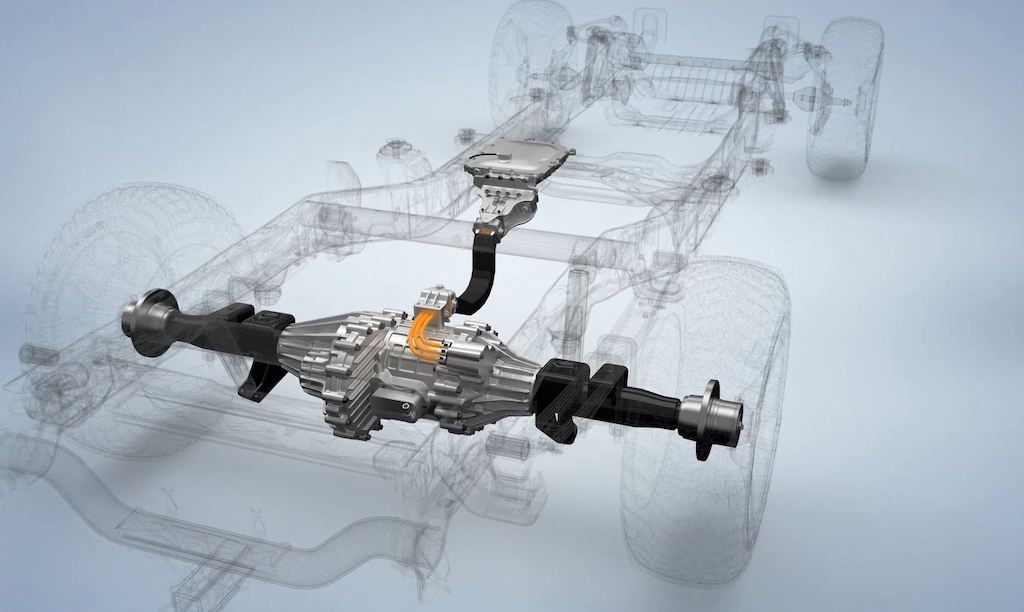

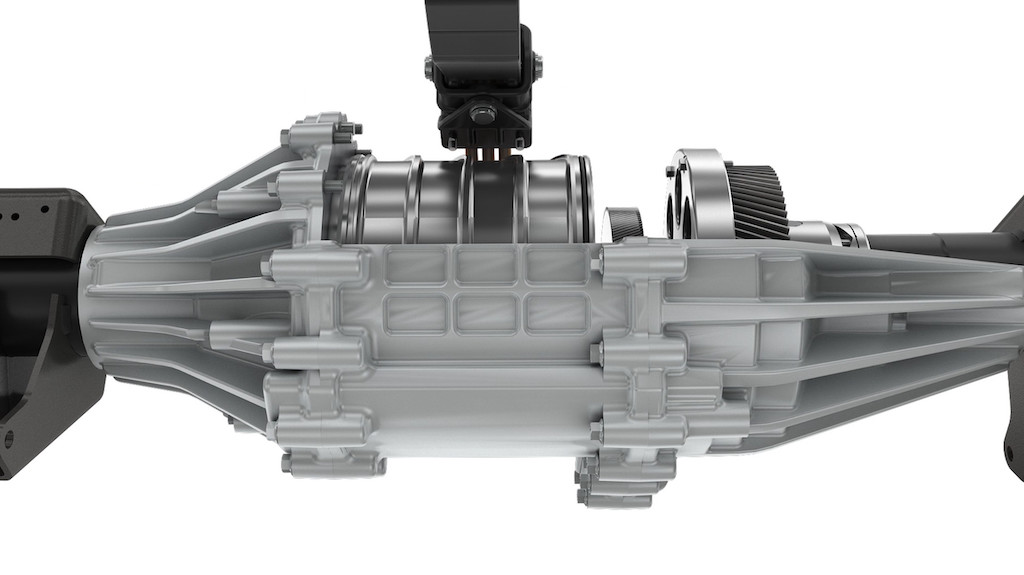

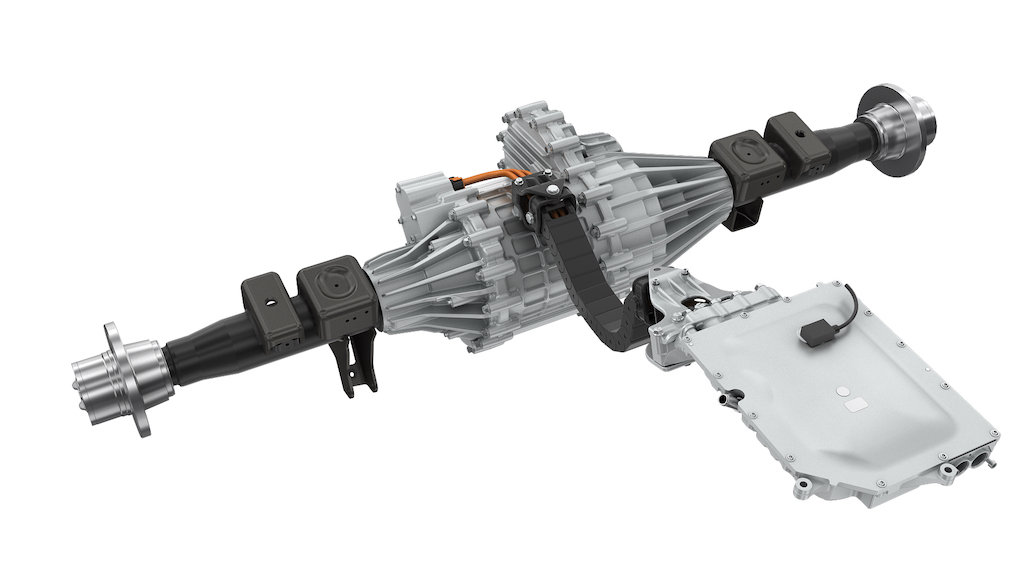

The eBeam system is a gearbox compatible with solid beam rear axle trucks and haulers. Also known as rigid or beam axles.

Vehicles with this scheme have been present for more than 100 years on streets and highways worldwide. The new system allows for power ranges that exceed 220 kW.

From Magna, they continue to accelerate their powertrain electrification capabilities to help automakers. All this to achieve a future free of harmful emissions for the environment.

This new example of transformation lays the foundations for a cleaner tomorrow that does not necessarily involve renovating the entire park. This gives continuity to vehicles that can continue to provide their services thanks to their powertrain’s modernization.

With this new technology from Magna, solutions can be scaled up, giving automakers the ability to electrify their trucks without sacrificing utility and functionality.

The eBeam integrates with a battery-powered hybrid or electric powertrain system through a frame-oriented design ready to support high payload vehicles. Along with this, it offers adequate power for continuous use.

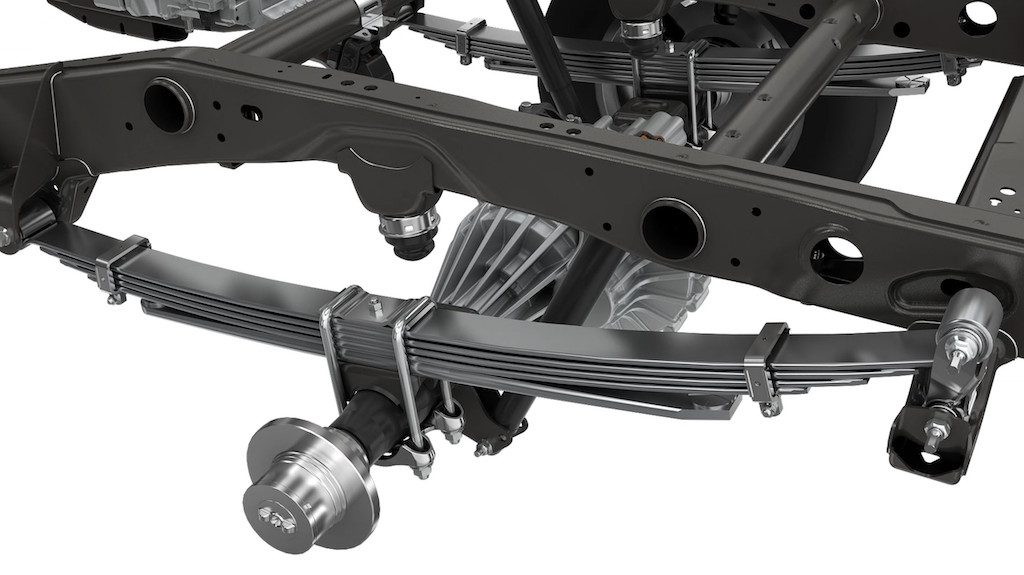

Explicitly designed to transition pickup trucks and light commercial vehicles to the full battery or hybrid electric powertrain systems, the eBeam integrates with existing truck architectures without requiring unique suspension, chassis, or brake systems.

This approach presents an economical solution that helps bring new electrified trucks to market faster while preserving towing and payload capabilities.

For Tom Rucker, president of Magna Powertrain, this “is a bold effort to electrify trucks, whose owners demand towing and hauling capabilities they are used to today, and we have done it with our eBeam technology.”

Rucker adds that “we know that axles are central elements of a truck’s strength, and we are excited to have developed the first significant improvement to the solid beam axle in more than 100 years.”