One of the keys to Tesla’s strategy has been to try to produce as many components as possible in-house. A bet that has led them to manufacture from their engines, cargo systems, to the seats. Now they are even betting on their own battery production that will go a step further with their own cells’ design. Jim Hackett, Ford CEO, does not share one way of tackling the electric car market.

In an interview with the Autonews portal, Hackett has stated that he has had meetings with different advisers during his arrival at the helm of the brand. After an intensive study, they have concluded that it is not economically worthwhile to carry out his battery production.

The cost of building the facilities has no guaranteed return that would be necessary to justify the investment. Ford will continue with its strategy of buying batteries from third-party companies, such as LG or Panasonic. Something that also for the head of the brand of Detroit will allow them to access a wide variety of proposals, being able to select the most competitive at all times.

One of the curiosities on which Ford has relied for this decision is the report presented by Hau Thai-Tang, head of product development and purchasing, which has indicated that to justify setting up a battery factory, they would need an initial production of between 100,000 and 150,000 units per year. The manager assumes that: “We do not have that volume initially to justify this capital expenditure.”

At the same time, Thai-Tang has stated that it is not out of Ford’s question to change its mind when the sales volume of its electric cars increases. But until then, no decision will be made.

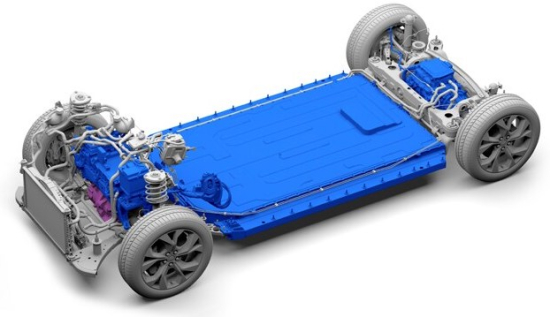

Interestingly, Tesla is taking advantage of the tremendous advantages of producing its batteries at its Nevada facility, which is responsible for assembling the battery packs with Panasonic.

According to a Forbes report published last January, kWh’s cost fell by 45% between the years 2016 to 2019. In practice this means that the cost of production of Tesla vehicles fell around at $7,000 on average.