Hydrogen has become one of the great objectives to accelerate decarbonization. A vector that has excellent potential in some sectors but faces significant challenges. Among them is the question of its transport, which has been raised from the traditional tanker trucks to its transformation into ammonia. From Germany comes a solution that will allow both natural gas and hydrogen to pass through the same conduit, which can simultaneously facilitate the transport of both elements.

This design has been created by a group of researchers from the Fraunhofer-Gesellschaft institute, who have developed membrane technology capable of efficiently separating gas and hydrogen at a low cost.

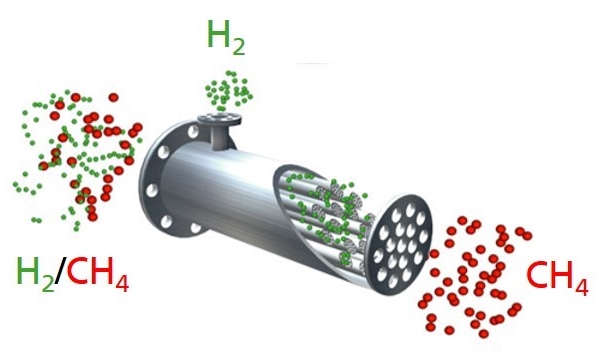

This technology makes it possible for the two substances to share conduits in a gas distribution network, separating when they reach their destination. Something that for its designers can be a significant step forward in the transport and distribution of hydrogen as an energy source.

To achieve this, the team has used ceramic-based materials while working to find other components that complement it, such as carbon. A carbon that forms an ultra-thin layer on porous ceramic substrates acts as a membrane, allowing natural gas and hydrogen to be separated.

There are several processes involved in membrane production, starting with custom polymer synthesis. Polymers are substances made up of branched macromolecules. They are then applied to the porous substrate. When the polymer is heated and deprived of oxygen simultaneously, it forms a carbon layer on its surface. Carbon pores are less than a nanometer in diameter, and this makes them practical for gas separation.

During the separation process, hydrogen and natural gas are pushed through the tubular modules. Smaller hydrogen molecules enter through the membrane’s pores and reach the outside in gas, while the larger methane molecules are retained.

According to those responsible for the project, the result is hydrogen with a degree of purity of 80%. Subsequently, they filter the residual natural gas in a second separation step, with a final result of purity of more than 90%.