The arrival of electric mobility brings the end of some of the elements that have defined the automobile throughout its more than one hundred years of history. Shifting gears has been a hallmark of driving any internal combustion vehicle for decades.

Despite the evolution of the gearbox and the popularization of automatic gearboxes, electric cars’ arrival is before and after an essential element when driving; the gear change.

Despite the industry trend to increase the number of gears to optimize the endothermic propellant’s performance and achieve lower vehicle emissions, modern electric cars dispense with the complexity of this element by including a single fixed ratio, two at the most in the case of Porsche.

Although the absence of a traditional gearbox is a characteristic that contributes to a more pleasant drive that highlights the linearity of the power delivery of the electric ones, the lack of this element reduces the weight of the vehicle, reduces the number of mechanical elements, and therefore its maintenance.

But the absence of various gear ratios is also a handicap for zero-emission cars.

Today, every available electric vehicle (except the Porsche Taycan) has a single-speed transmission since the electric motor does all the work through a single gear.

Electrics can afford to do without a transmission with different gears thanks to the enormous operating arc of electric motors, which also have the advantage of being able to be used from their maximum revolutions to zero without stopping or stalling.

The ability to widely exceed 10,000 rpm and even double this figure, at full speed, along with the feature of being available on-demand from the throttle at any time, allow the electrics available on the market to do without an essential element until now. But these advantages do not imply that all the motor torque is available from zero to maximum revolutions per minute since from a certain speed, the torque begins to decrease; besides that, at high speed, it is not possible to optimize the performance or revolutions of the motor by having only one speed, so it ends up consuming more energy than necessary.

Automakers deal with this in several ways, designing the single gear ratio for city use. For this reason, many of the electrics for sale also limit their maximum speed.

The problem of having only one gear ratio is tackled in different ways by each manufacturer. One of the industry benchmarks today, Tesla, originally intended to use a two-speed gearbox, as Porsche has finally done. Still, due to complexities, difficulties, and cost, they opted for their original solution. The California brand opted to use a two-speed ‘gearbox’ by separating the two gears in two engines; that is, it used two different gear ratios in each of the engines that incorporate its AWD four-wheel drive cars.

With this solution, Tesla simulates a two-speed gearbox using a double engine in its vehicles, where the smallest development is located in the rear engine, designed for the sudden accelerations that characterize its cars. Simultaneously, the longest is installed on the front engine that is responsible for ‘pulling’ the vehicle on the highway during higher speed journeys.

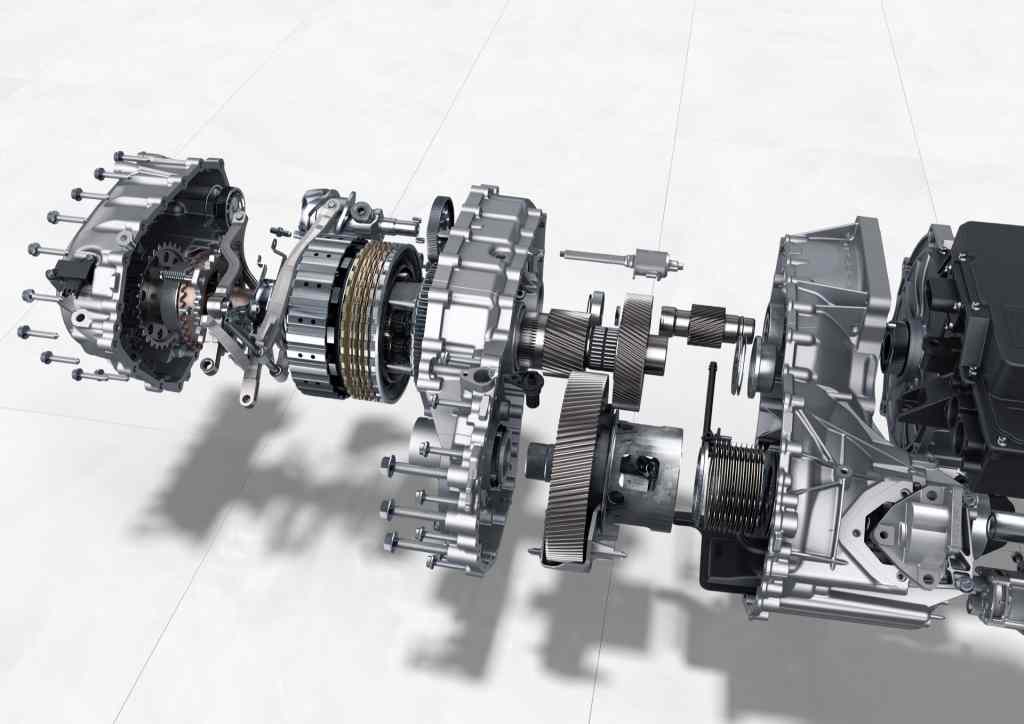

Porsche, for its part, was the first manufacturer to incorporate a two-speed transmission in its Taycan, a step that many other large manufacturers can now follow as solutions such as those from ZF or Inmotive arrive on the market, which allows managing the shifting gears without the exuberant torque of the electric motors destroying the transmissions and with almost no interruption of the thrust curve that makes this type of vehicle unique.

The advantages of a solution with more than one development can allow electric vehicles to improve efficiency when transmitting energy, optimizing the system on the one hand, and increasing performance.

From Canada comes an alternative

In 1995, the Toronto startup Inmotive’s jump into the universe of electric vehicles was based on the fact that their motors use much more energy than they need to carry out their mission. The Canadians’ goal was to offer an efficient, economical, and compact alternative to optimize the performance of zero-emission vehicles.

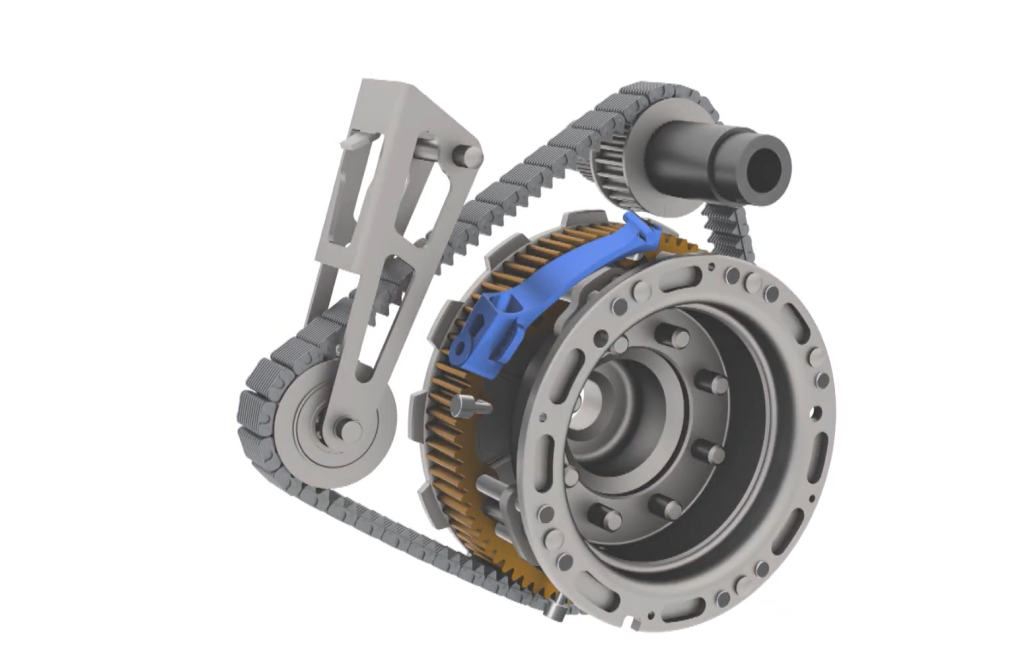

What differentiates the two-speed transmission baptized as Ingear concerning other solutions on the market is that it incorporates a continuous chain transmission that allows, according to the company, that “energy flows continuously between the engine and the wheels, even during the change.” This being the solution that can turn around the future of future electric car transmissions.

As if it were a bicycle derailleur, the Canadian gearbox’s operation replaces the highest development with a retractable gear that is gradually ‘collected.’ At the same time, a continuous toothed belt simultaneously engages the lower gear ratio, avoiding pauses in the traction typical of the conventional gear change.

According to the Canadian company, the advantages of this innovative engineering solution are to optimize vehicle efficiency up to 7.1% under the WLTP-3 cycle and 6.7% in the EPA-Combined cycle.

To demonstrate how their solution works, the Canadians installed their gearbox in a Kia Soul EV and allowed some journalists to test their unit who share their impressions in the video below.

Once these types of alternatives are consolidated, using this type of two-speed gearboxes with continuous change will maintain the linearity in acceleration and power delivery that distinguishes EVs while reducing the battery’s size. The inverter and the motor, further increasing the autonomy of each car.

Achieving a more efficient car means using smaller batteries to obtain the same range, which reduces the vehicle’s purchase price, the number of raw materials to build the batteries, and the energy production required to complete each trip.