Elon Musk, Tesla CEO, has just confirmed that the Model Y produced at Giga Berlin will be the firm’s first vehicle to feature structural batteries and the brand’s new 4680 tabless cells, two firsts revealed just a few days ago. during “Tesla Battery Day.” Until now, it was believed that these novelties were going to be released by the Model S Plaid sports sedan, the Semi truck, and the Cybertruck pick-up.

“Berlin will use 4680 cells, structural batteries, and unique castings front and rear. Also, [it will also debut] a new painting system. Many new technologies will be produced in Berlin, which means significant risk. Fremont and Shanghai will transition in two years when the new technology is tested. “

On the other hand, Musk has also communicated that the company will use LFP (that is, lithium-ferrophosphate) batteries in its medium-range electric cars and stationary storage systems. Cobalt-free LFP chemistry combines low prices with long pot life; in return, its energy density is somewhat poor, although Tesla should be able to tackle this setback by using solutions such as the aforementioned structural batteries.

As its name suggests, a structural pack consists of the body of the vehicle itself acts as the housing for the batteries. According to Tesla, this will improve autonomy by 14%, reduce weight by 10%, and significantly simplify their cars (about 370 fewer parts will be used), reducing production costs and achieving a much more structurally rigid than any other vehicle, which in turn will have a positive impact on both passive safety and dynamic performance.

In Musk’s words, the battery pack will be a unitary structure in which the cells themselves will transfer the shear stresses to the upper and lower steel sheets, eliminating most of the central parts of the vehicle structure, achieving improved torsional rigidity and moment of inertia. Although it is not confirmed, we want to think that the lower steel sheet will be removable, which would allow repairs to the pack without having to disassemble half the vehicle.

Berlin will use 4680 cell with structural battery pack & front & rear single piece castings. Also, a new paint system.

— Elon Musk (@elonmusk) October 7, 2020

Lot of new technology will happen in Berlin, which means significant production risk. Fremont & Shanghai will transition in ~2 years when new tech is proven.

The mainframe of the Tesla Model Y manufactured in Giga Berlin is expected to be produced following the same principle that we will find in the front and rear frames, each made up of a single massive-size cast piece made of aluminum. With this technology, Tesla will stop using dozens of pieces welded together to make large structures. According to Musk, in an accident, the shock-absorbing rails can be cut and replaced with a new bolt-on piece.

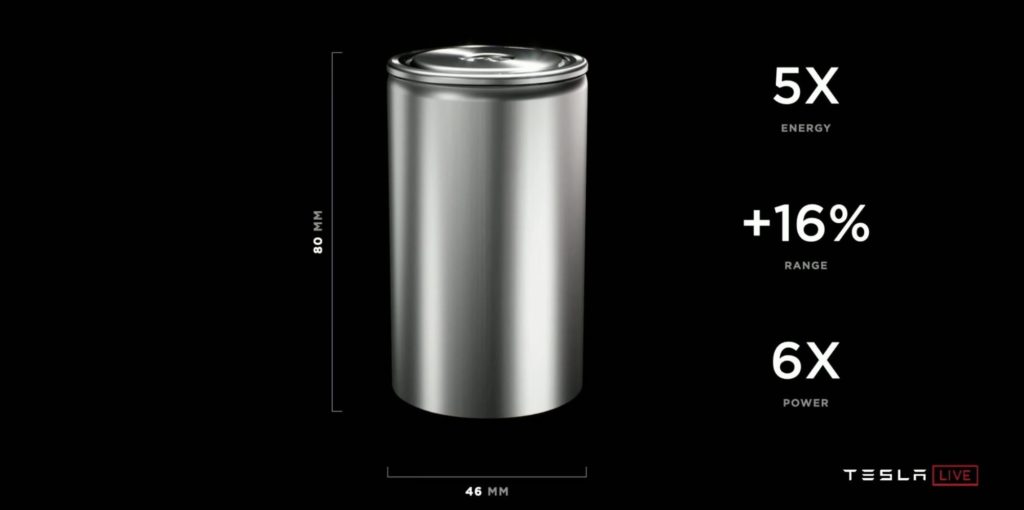

The new 4680 cells should allow an increase in the autonomy of 16% and a cost reduction of 14%. Among other firsts, these cells will feature a “tabless electrode” design, which eliminates the tabs used at the cathode and anode to connect to the housing terminals, simplifying production, improving costs and performance, and reducing the ohmic resistance, since the current does not have to go from the electrodes to the reed.

These cells will also allow faster and more efficient manufacturing: each of the new production lines will reach 20 GWh per year of capacity (an improvement of up to seven times compared to current processes), reducing the necessary investments by 75% per GWh produced and allowing the construction of Terafactories up to 10 times smaller than the current Gigafactories. By the end of 2021, Tesla estimates that it will have an annual production capacity of 10 GWh of 4680 cells (more than enough to manufacture about 100,000 Model Ys); however, in 2022, mass production will begin, reaching nearly 100 GWh per year.