Tesla has applied for a patent for new electrolyte compositions for anodeless lithium-metal cells. The request, which has been submitted by the company’s research team led by Jeff Dahn, is for a lithium difluoro borate (oxalate) electrolyte and lithium tetrafluoroborate salts for anode-free lithium-metal cells.

“Rechargeable batteries are an integral component of energy storage systems for electric vehicles and the electrical network […]. Some of these rechargeable battery systems are lithium-metal, and others are lithium without anode. Lithium-metal and anode-free lithium batteries have certain advantages over traditional lithium-ion batteries because they have a higher energy density.”

“Cells without anodes are also less expensive and easier to assemble. However, the challenges of lithium-metal batteries and lithium-anode batteries have prevented their widespread adoption. The improvement of certain characteristics of these systems will allow a more generalized use. For example, the development of electrolytes that enable commercially acceptable durability […]”.

The electrolytic compounds described in the patent application allow improving the longevity of this type of batteries, which exceeds the current ones in aspects such as energy density and cost. Thus, the new chemicals developed by Jeff Dahn and his team for Tesla could spell a revolution within an industry that is primarily focused on solid electrolytes.

However, in the request, you can see some of the results of the tests carried out on the new cells, and everything seems to indicate that the 50 charges/discharge cycles have not been exceeded. Therefore, Tesla will still have to undergo much more stringent testing (that is, many more cycles) to verify its commercial viability.

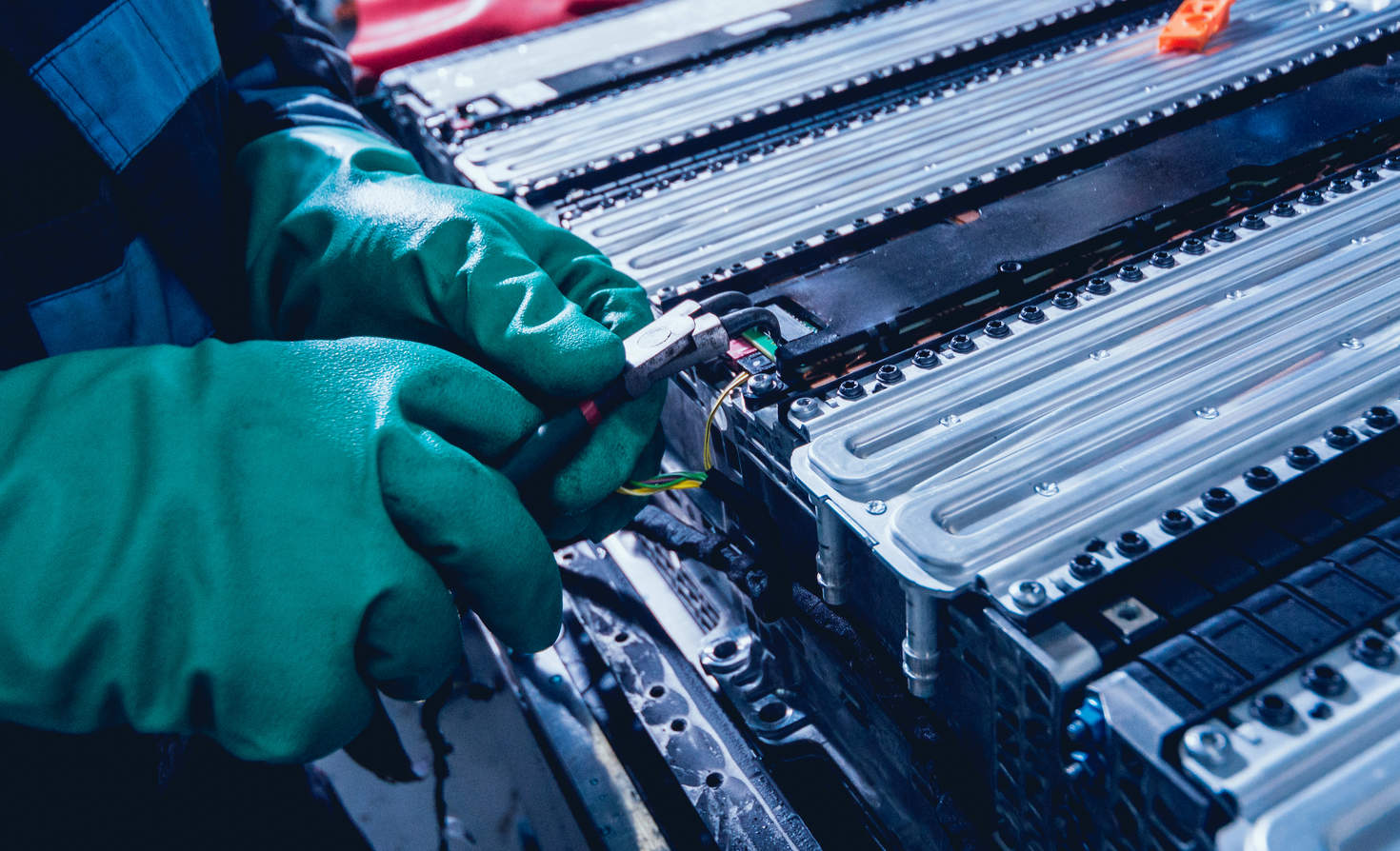

It is possible that Tesla will reveal more details of these new cells on September 15 during the “Tesla Battery Day.” An event in which the company will reveal to the world its latest advances in the field of batteries, also showing the production process from its developed cells (the firm currently has a pilot manufacturing line in Fremont).