From a mechanical point of view, electric cars are much simpler than gas cars: compared to the dozens of moving parts that make up an internal combustion engine, electric thrusters have only one. Besides, in most cases, complex gearboxes are dispensed with, which further increases the simplicity of these vehicles. But to what extent is an electric motor durable? The VehicleSuggest page has made an interesting analysis in this regard.

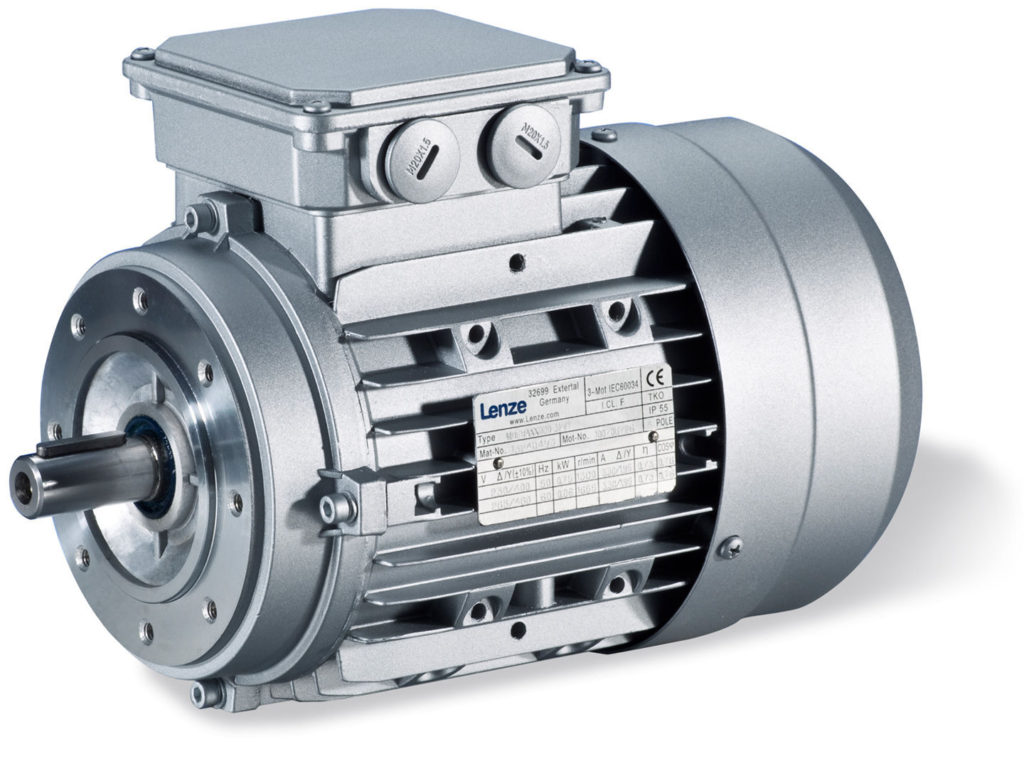

Today, the most widely used motors in electric cars are permanent magnet synchronous motors, alternating current induction, reluctance, and direct current. A simple architecture is shared in all cases, as they do not require additional oils, belts, etc. Furthermore, its operating temperature is around only 40ºC.

Some of the factors that affect the life of electric motors are sudden workload changes, fluctuations in input power, improper installation, humidity, and temperature. Despite this, and provided it is used under normal operating conditions, an electric motor can last the equivalent of between 15 and 20 years (or higher) and 400000+ mile range (Tesla has passed the 1 million mile test).

When creating an electric car, manufacturers must take into account various aspects to ensure its durability. For example, irregularity in current and voltage supply can lead to higher operating temperatures or motor failure. Current harmonics, transients, and voltage imbalances are some of the points to be controlled to ensure the proper functioning of the electrical system.

Mechanical overload compromises the motor components (insulation, couplings, bearings, etc.), which reduces their efficiency and can cause premature failure. Therefore, it is essential to design efficient engines with adequate performance.

Some of the factors that can lead to premature breakdowns in electric motors are the following:

Pollution: The accumulation of chemicals, dirt, and dust is one of the leading causes of an electric motor’s failure, as the presence of foreign particles inside the engine deteriorates the bearings, increasing wear and vibrations.

Overheating: An increase in the temperature of an electric motor can cause malfunctions; This is usually due to an operating environment with a high temperature or inadequate quality power supply.

Vibrations: Often caused by faulty positioning of the motor on an unstable or uneven surface, or due to corrosion, misalignment, etc. Vibrations dramatically reduce the life of the engine, as noted above.

Insulation failures: The degradation of the insulation of the windings due to physical failures, corrosion, and overheating can cause short circuits and leaks.

Electrical overload: an excessive current flow (above the safety specifications) overloads the motor, causing it to fail. Low voltage can result in excess current in an attempt to maintain torque, while excessive energy can also overload the system.