Among other technical innovations, Tesla has long been working on “unibody” manufacturing. Replacing current structures made up of dozens of stamped steel parts welded by structures made up of a single cast piece made of aluminum.

The first step in this ambitious manufacturing strategy is Model Y, whose lower rear structure is made up of 2 unique large pieces, compared to the 70 pieces that make up the same structure in Model 3, the Model from which the Model Y is derived. According to Elon Musk, this process significantly reduces the cost of robots to weld the different parts of the car body, also making manufacturing easier.

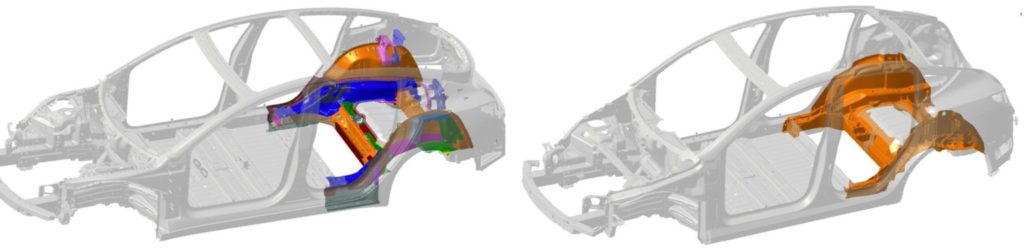

Now Tesla has shown for the first time a graph comparing the Model 3 and Model Y’s lower rear structures. The company has also shared images showing both the Model Y’s massive function parts and Model 3’s welded parts.

This process, described by Musk himself as revolutionary, will go further in the future. The executive has confirmed by the end of the year Tesla will be able to manufacture said structure from a single piece instead of two as it is now. According to him, this manufacturing method will reduce the weight of cars and improve aspects such as vibrations.

At the moment, Tesla has not wanted to confirm when it will begin to implement this interesting solution in other cars. The company will advance with lead feet, as it does not want to compromise its current production capacity. Therefore, it is expected that this constructive method will gradually be implanted in the new models of the brand (some sources affirm that the Cybetruck pick-up will go one step further than the Model Y, making intensive use of this technology in its manufacture).

Surely Giga Berlin, the company’s fourth gigafactory, will also incorporate this attractive solution into its production lines from the beginning. It is highly likely that, being a newly built factory, Tesla will decide to use its new manufacturing method more widely than in vehicles produced at the Fremont plant.