Tata Motors (India) published the first news of a revolutionary battery that did not need to be recharged, and that could offer 1000 miles of range, eight years ago.

One of the keys to this metal-air technology is that it does not need to be recharged. Instead, we have opted for a system where we only need water and some aluminum plates. This, when oxidized, forms aluminum hydroxide and generates the current, being able, in addition to offering significant autonomy, to recover its capacity in a few minutes simply by adding water.

But this reaction is not reversible. The aluminum anode dissolves and forms oxide deposits. Phinergy says they have improved the system with a membrane that maximizes metal use, achieving up to 20 miles for each half-pound plate. With 50 plates, 25 kilos, we can travel 1000 miles. Of course, the water will have to be changed before, being in the prototypes every 183 miles. And at the end of the 1000 miles, the aluminum plates will also have to be changed, which they estimate will cost about 90 dollars.

This technology might not make much sense in small cars or motorcycles. But its application does have a lot of potential in buses or trucks, and mainly in places where the electricity supply is not quite good. Something worth enough to attract India Oil’s attention which has acquired a Phinergy to develop this system.

Now they have confirmed the first tests on industrial models of this technology in collaboration with Tata Motors.

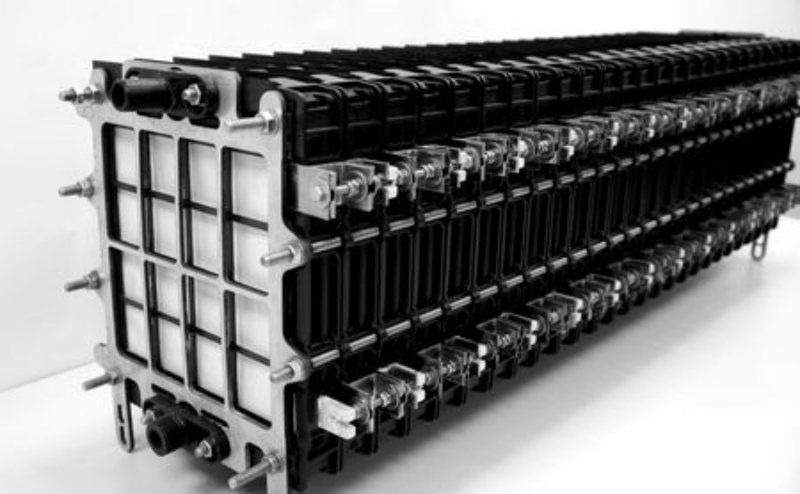

For this, a battery made up of 25 metal-air cells placed in series has been developed and installed in a group of electric buses and trucks. Vehicles that can make the most of a system that their developers indicate can achieve the best energy density on the market, with about 8 kWh per kg. A figure that they compare with the 1 or 1.5 kWh per kg of lithium in the current ones.

Some studies give aluminum-air batteries specific energy of 1,300 Wh/kg, about ten times more than lithium-ion batteries. Still, in this calculation, water weight is not taken into account, which lowers the specific energy to about 470 Wh/kg. A figure that is also very striking.

Among the main benefits of the development team is that they do not need electricity to charge. Something that allows them to operate in remote areas or with problems to deploy their recharging network. They also indicate that it is a more sustainable system since aluminum can be 100% recycled. They also add another critical factor: by dispensing with liquid electrolytes, it is a safer battery and capable of withstanding much higher temperatures without degrading.

If, from what it seems, all are advantages, why has this technology not yet triumphed? Its designers give us an explanation. Despite achieving a high energy density, this battery has not yet managed to achieve a high power output. Therefore, for the moment, it is necessary to use a lithium battery that acts as an intermediary with the propulsion system, being the metal-air pack in practice an autonomy extender.

But the potential of this system is on the table. If they manage to solve this problem, we would undoubtedly be facing technology with the capacity to electrify a large number of applications, both in transport, as storing energy for electrical networks, or as a backup for more remote communication towers.