“Tesla will give a giant contract for a long period [to that company] that extracts nickel in an efficient and environmentally sustainable way,” Elon Musk recently said during a conference call after the launch of Tesla’s second-quarter financial results.

Nickel is one of the critical components of lithium-ion batteries today, especially those with a low cobalt content such as the NCAs produced by Panasonic or the NCM 811 of origin LG Chem (both types of cells are currently being used by Tesla in different versions of Model 3).

The need to stop relying on expensive and low cobalt is resulting in an increased demand for nickel. However, recently Tesla reached an agreement to ensure the supply of cobalt for its batteries, which seems to mean that it will continue to use this raw material for a time in its cells.

According to the executive, currently, the most limiting growth for Tesla is the high price of batteries. Everything seems to indicate that the company’s future developments will focus on solving this problem rather than on improving the energy density of their cells. This aspect is likely to evolve more slowly from now on.

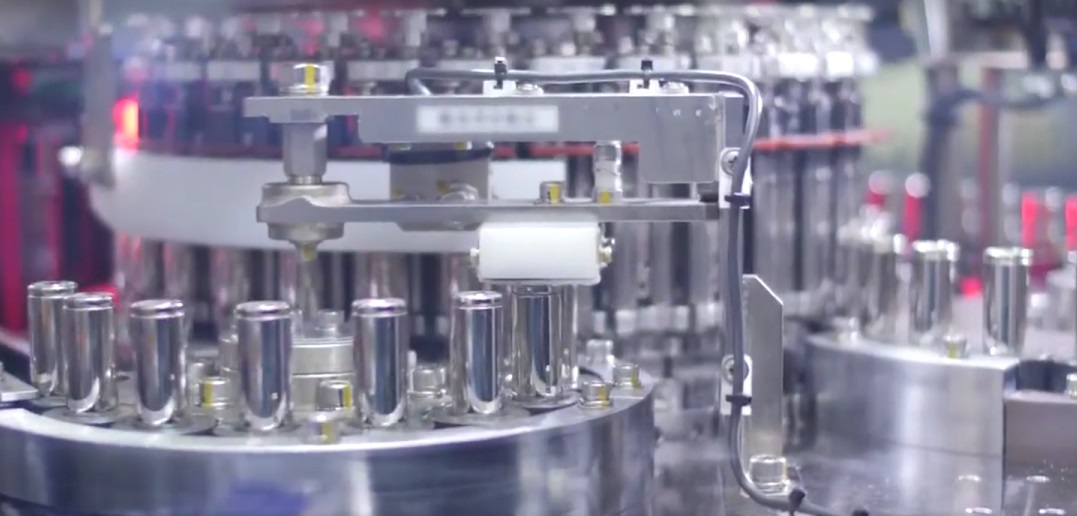

It is expected that during the “Tesla Battery Day,” scheduled for September 15 this year, the firm will reveal essential developments concerning its developments in the field of batteries. Initially, the company will introduce a more straightforward cell production process and new chemistry developed by its internal research teams.

Today Tesla has dealt with Panasonic, LG Chem, and CATL. The company has recently strengthened its association with the first, and Musk has confirmed that collaboration with the other two will also be expanded in the short term. Additionally, Tesla is working on his own on a project to develop and manufacture its cells.