Hideaki Horie is a Japanese engineer with experience working at companies like Nissan, and who has now revealed the first details of an exciting job that seeks to give a 180-degree turn to the way we produce batteries. A polymer system that provides the company with its name has received the support of the Japanese industry to begin its first tests.

Horie’s idea is to change the way cells are manufactured today, where factors such as the need for closed spaces with expensive air filtration systems are involved so that contamination does not enter the cells. Something that causes starting a new facility to cost significant amounts of money and takes years to get started at an industrial level.

A system is more similar to the production of semiconductors that this Japanese technician wants to transform into a format similar to that of steel production.

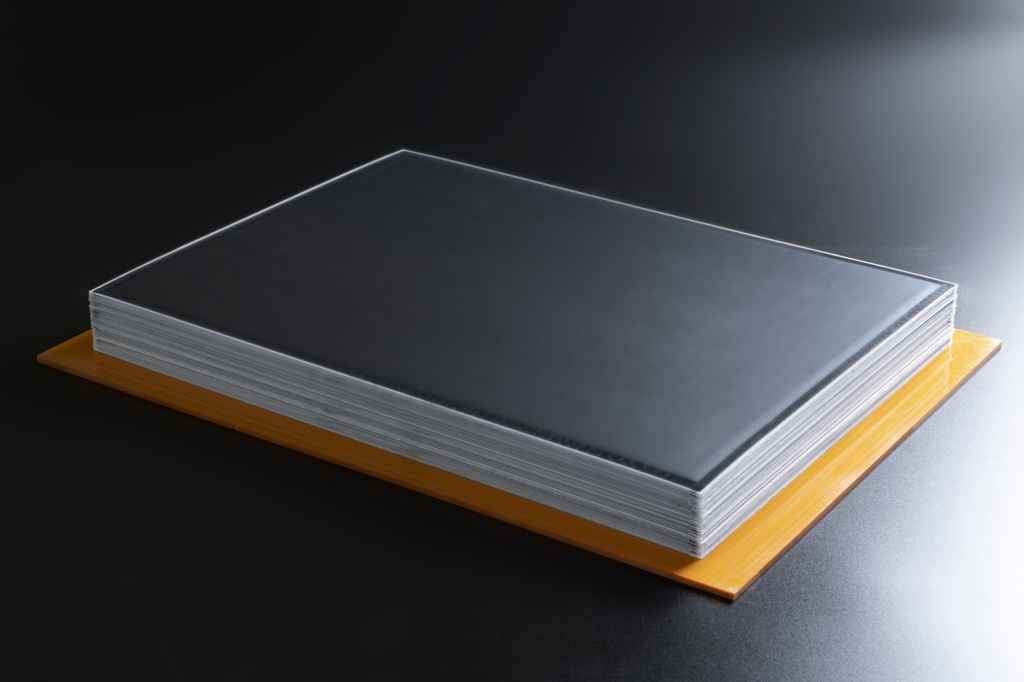

This new system would mean replacing the battery’s essential components (metal-coated electrodes and liquid electrolytes) with a resin construction. An approach that dramatically simplifies and speeds manufacturing in a process that enables the production of sheets up to 10 meters long can be stacked on top of each other to increase capacity.

To this is added that the use of polymers will make the stability of the cells much higher, and according to its creator, thanks to a bipolar design, which eliminates current energy bottlenecks, will allow the entire surface of the battery to absorb overvoltages in cases such as an accident or a strong impact.

Among the challenges to overcome by technology is that polymers are not as conductive as metal, which can affect the battery’s charge capacity. Individual control of cells is also made more difficult by their bipolar design.

But the main challenge facing this initiative is competition from the giant lithium battery manufacturers, which are achieving an unprecedented economy of scale, which allows for constant cost reductions. It is something that polymer technology is far from attaining despite the promise of making a cost reduction of 90% compared to current systems.

This could lead this system to be placed as an alternative in niche markets, such as stationary batteries, residential, and those responsible for regulating the electricity grid, and storing surplus renewable energy. Also, in sectors such as aviation, safety is crucial in the face of manufacturers’ confidence in electrifying their aircraft.

Now it will be time and facts that judge whether we are facing a real revolution in the way batteries are manufactured or another attempt to remain in the pipeline.